| Cismac Electronique > Hydropower® |

|

| Cismac Electronique > Hydropower® |

|

Produce your electricy wherever you need it

|

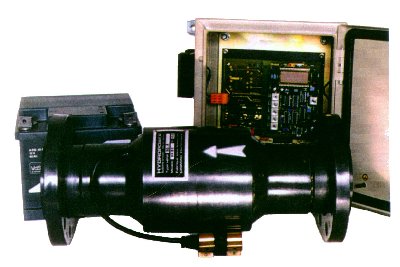

The mini power-station HYDROPOWER, placed on a pipe of water

supply network allows to furnish electronic devices used for the

automatisation and centralised controls of isolated sites with 12 or

24 Vcc. Set up in a sight-hole or in a room of valves, HYDROPOWER is

protected against vandalism and atmospheric disturbances. This

equipment is delivered in DIY of three parts. it is easy to put into service. Principle: The HYDROPOWER device is composed of a mini turbo alternator and an impervious battery which charge and discharge are controlled by an electronic unit of regulation and protection. The mini turbo alternator, moved by the water flow, loads the battery to supply a permanent electric power in spite of the intermittent cycle operating in the hydraulic networks. The different parts are dimensioned in accordance with the hydraulic conditions, and in order to supply the necessary electric power with a minimum pressure drop. Applications: The HYDROPOWER device is able to supply with 12 or 24 Vcc every appliances of low permanent consummation such as: flowmeter, level transmitter, telecontrol remote units, etc... or on the contrary, electric device of more power but which daily average consummation is low, such as dosing pump, solenoid valve, motorised valve, etc... |

|

|

Electronic control unit: It makes the tension of charge regular according to temperature, the current is self-regulated by the battery according to its rate of discharge. To avoid important discharges, the circuit of utilisation is cut by a static relay as soon as the battery tension falls to 11V (22V). It is automatically restored as soons as the tension goes up again to 12V (or 24V). A signal "battery alarm" points out that the tension went down to 11.8V (or 23.6V). A signal "end of charge" shows that the battery has recovered its normal charge. These two informations are generally transmitted by telecontrol. Their reading allows to control the running order of equipments. In some cases, they can be used to run the mini turbo alternator by remote control. |

These two informations of telecontrol are delivered by photo-isolator free of tension. To avoid any risks of damage during the setting work, the electronic board is protected against inversions of polarity of the battery, and against the overload or short-cut by a quick electronic circuit breaker. The impervious battery doesn't need any upkeep. Its capacity is calculated in order to prevent, in normal working conditions, the rate of discharge doesn't exceed 20 to 25% the nominal capacity. This is to assume a maximal life and go a good work reserve.

Electric power: The alternators connected on the turbines have a power of 75, 100 or 200 VA. The daily avaible power is relevant to the working time. In order to avoid the lost of charge, the supplied power just fit the requirements, when establishing the plan of setting up.

The maximum pressure of use is 10 bars on PVC pipes and 16 bars on metallic pipes. For pressures superior to 16 bars, the mini turbo alternator can be delivered in a metallic socket.

Options: The control unit is usually fitted out with the complementary board HYDROTEST1 which permit posting up the running parameters of the device.The boards such as HYDROMAT, while piloting an solenoid valve or a motorised valve, make possible the working using local parameters such as the battery tension or the water level in the tank, the operating postponed by the clock and the operating by remote control from the master station. These boards allow to use the HYDROPOWER device on tanks through which a little volume pass daily, on water catchments which flows after change with the saisons, and on sites where consummation increases a lot during summer.Other kinds of boards make the conversion of tension 24/12V or 12/24V and operate like a static relay of power to manage a motorised valve.

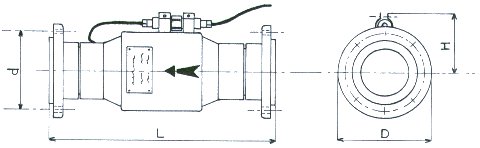

| Reference | Flow (m3/h) |

Hydraulic connection |

L±5 (mm) |

D (mm) |

H±5 (mm) |

d (mm) |

Weight (Kg) |

| HPW75 HPW80 HPW90 HPW100 HPW110 HPW125 HPW125 |

6-20 15-40 25-50 50-70 60-80 70-120 70-120 |

DN65 DN80 DN80 DN100 DN100 DN110 DN125 |

460 460 460 540 540 550 550 |

185 200 200 220 220 230 250 |

120 120 120 135 135 135 135 |

145 160 160 180 180 190 210 |

7.5 7.5 7.5 9.2 9.2 10.0 10.5 |

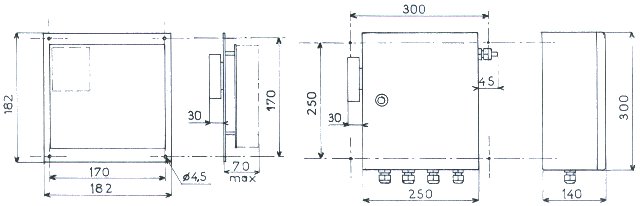

Stripped control board

Control unit

| top ©1998-2002, Cismac Electronique |  |